- Orbital Insight Blog

- Do you recognize the top 7 trends shaping supply chain management in 2021 and beyond? (Part 2)

Blog

Do you recognize the top 7 trends shaping supply chain management in 2021 and beyond? (Part 2)

Did you know that transnational supply chains represent 80% of global trade, touching a significant part of our daily lives? Are you aware that supply chains are the foundation on which all commercial and public sector operations depend? A disruption in the supply chain results in chaos everywhere, from the production line to the retail shop and the breakfast table! No surprise that supply chain management has become a pressing issue for CEOs at companies across industries of all sizes as well as military and defense organizations. In the first part of this two-part blog series, we discussed the top three trends - Visibility, Resilience, and Hyperconnectivity-shaping supply chain practices. In this second blog, we review the remaining four trends that will make a difference for years to come:

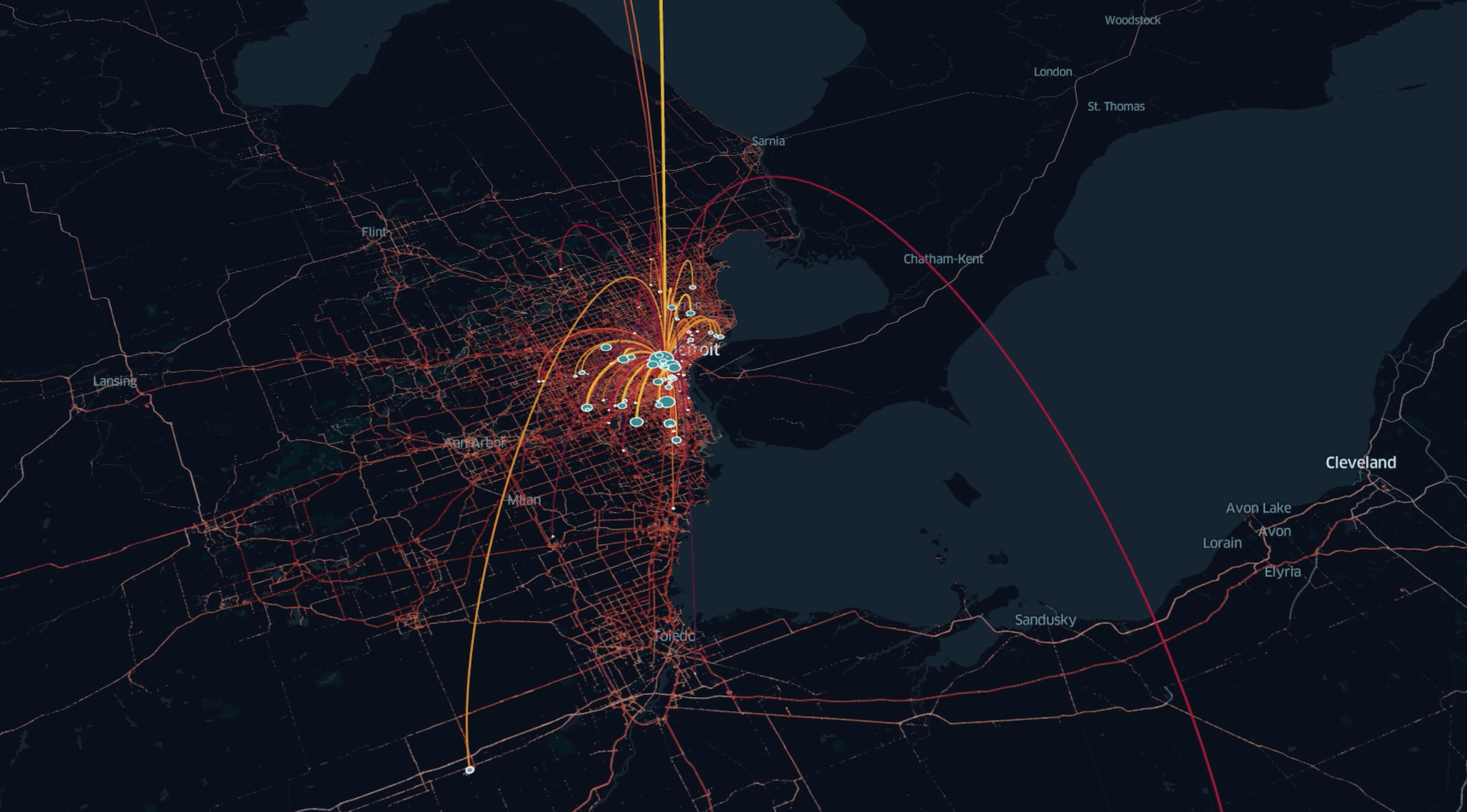

4. Sustainable Sourcing: The sustainability theme is gaining momentum primarily driven by pressure from NGOs, the government, investors, and consumers. Both B2C and B2B companies are increasingly becoming aware of environmental and social impact. Conscious of their brand image, many multinational companies must work only with suppliers that adhere to social and environmental standards. The biggest consumer companies are taking environmental issues such as air pollution mitigation, carbon emissions reduction, and forest management seriously. E.g., at Unilever, sustainability is a top priority. The British MNC is working with the geospatial analytics leader Orbital Insight, to help identify the individual farms and plantations most likely supplying the palm oil mills in their extended supply chain. The technology leverages GPS data, aggregated and anonymized, to spot traffic patterns. A consistent flow of traffic between an area of land and a mill suggests a potential link. Using Orbital Insight’s location intelligence platform GO, sustainability champions at Unilever get a clear picture of where harvested crops are coming from, down to the individual field. It allows Unilever to predict the possibility of issues such as deforestation and to take appropriate action.

In this era of climate change, we desperately need circular supply chains that eliminate waste and focus on reused, recycled materials. But, unfortunately, the circular supply chains are likely to remain relatively rare outside businesses that are local and simple in the near term, according to research from the University of Cambridge.

5. Agile Supply Chain: Gartner’s global supply chain survey revealed that 89% of supply chain professionals want to invest in agility. Factory lockdowns, transportation network failure, and a worldwide shortage of essential goods stemming from the covid pandemic exposed the vulnerability of supply chains. As a result, there is an urgent need to pivot to a strategy that boosts agility and makes the supply chain more responsive. The traditional supply chains were focused on Lean - eliminating wastes and reducing costs. Agile supply chains, on the other hand, focus on flexibility and adaptability. Agility means responding to fluctuating market dynamics - changing consumer behavior, competitive plays, and economic conditions efficiently. And one approach towards agile supply chains is leveraging advanced analytics. Organizations are making massive investments in technology to make informed decisions about demand forecasting, pricing, and business risk analysis to respond to potential disruptions. Anomaly detection and predictive analytics can boost agility and help organizations to respond to disruption much better.

6. Risk Management: A vast majority of organizations lack formal processes to manage supply chain risks. Often the problem is finding out where to start. In the case of multi-tier industrial supply chains that span countries, there are thousands of suppliers contributing to a single product. For example, an automaker has 250 tier-1 suppliers, a reasonable number to track and manage. However, the number of suppliers jumps to 18,000 across the entire value chain, growing exponentially in complexity and risk. How can you identify all suppliers providing the raw material in the upstream supply chain to the final assembled system? Businesses with multi-tier supply chains need specialized risk management solutions. The first step is to implement tools that enable organizations to trace the complete supply chain to get visibility and traceability beyond direct suppliers. Next, supply chain leaders need to build a framework to assess risk, and finally, monitor that risk. This McKinsey report suggests that organizations must build robust programs to manage both known and unknown supply-chain risks and give a practical approach to manage risk. It is important to note that persistent monitoring is one of the critical success factors in identifying supply chain risks.

7. Intelligent Supply Chains: Gartner predicts that through 2024, 50% of supply chain organizations will invest in applications that support AI and advanced analytics capabilities. Process automation, cloud-based analytics, and real-time transportation visibility solutions are some technology areas that have already made inroads in the supply chain world. Tomorrow’s supply chain will be intelligent, driven by data, AI, and machine learning. Supply chain 4.0, the digitization of supply chains, combines IoT, robotics, and advanced analytics to redefine the supply chain - faster, more flexible, accurate, and efficient supply networks.

As product life cycles get shorter, products become more personalized, and more consumers gravitate towards sustainable, ethical companies, supply chains will become transparent, resilient, responsive, and intelligent. Supply chain intelligence powered by location data and geospatial analytics can help you embark on your supply chain transformation journey. To learn more about our supply chain solution, check out our latest video: