- Orbital Insight Blog

- Do you recognize the top 7 trends shaping supply chain management in 2021 and beyond? (Part 1)

Blog

Do you recognize the top 7 trends shaping supply chain management in 2021 and beyond? (Part 1)

Whether you are looking for high-performance computing servers, new energy-efficient appliances, or the latest model of your favorite car brand, you may be aware of the increasing demand and tight supply situation. Out-of-stock items, limited inventory, and high prices have become a norm. For example, used cars prices are up 30% from a year ago. The global shortage of semiconductor chips has had cascading effects on the availability of industrial and consumer products. The trickle-down effects of the Covid-19 outbreaks have brought supply chains into the limelight. The executive teams at multinational companies are laser focussed on supply chains, chief supply chain officers (CSCOs) have the budget and mandate to transform operations. In this two-part blog, we look at some of the trends that are influencing supply chain management:

1. Transparency and Visibility: Transparency has become one of the most debated hot topics in the supply chain community. But what does it mean in the context of supply chains? According to Alexis Bateman, director of Sustainable Supply Chains at the MIT Center for Transportation and Logistics, there are two elements to supply chain transparency, Visibility and Disclosure. Visibility is accurately identifying and collecting data from all links in your supply chain. Disclosure is communicating that information, both internally and externally, at the level of detail required or desired.

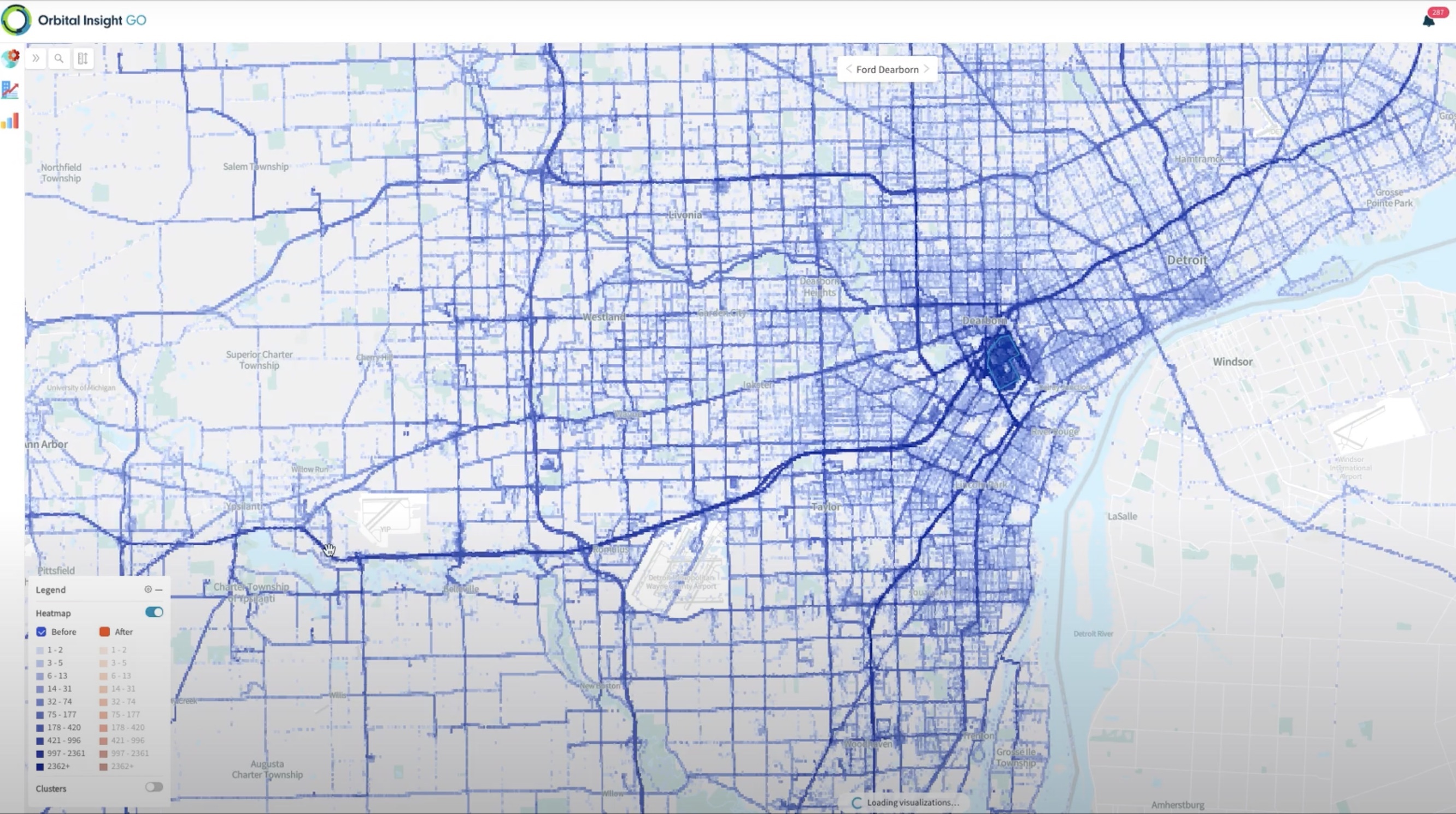

Based on your specific industry, pertinent government regulations, suppliers, and corporate culture, this can be a daunting task. Yet, there is pressure from governments, consumers, NGO’s and stakeholders for granular information about supply chains. There is growing awareness about environmental issues, climate change, and social responsibility. Savvy consumers ask questions about product ingredients and materials, where these ingredients are coming from, animal welfare, and child labor practices in the supply chains. The regulations are becoming more stringent, particularly in the food industry. And beyond compliance, there are additional benefits of transparent supply chains. Data shows that consumers are willing to pay more for greater transparency. Researchers at MIT found that supply chain visibility is a surefire way for companies to gain consumer trust and can even lead to increased sales from certain customers. Unfortunately, traditional supply chains were designed to be opaque. As a result, organizations have been investing in visibility solutions to bring transparency to supply chains. And this is an area where geospatial technology is playing a significant role. For example, a location intelligence platform can provide unprecedented visibility and traceability, allowing supply chain leaders to make informed strategic decisions that drive revenue and reduce risk.

2. Improving Resilience: A Gartner survey of more than 1,300 global supply chain professionals found that 87% of respondents plan investments in supply chain resiliency within the next two years. The CSCOs have to find a new balance between resiliency, cost-efficiency, and fulfilling increasing customer demands. The supply chain technology leaders are grappling with issues such as where to invest and how to prioritize? McKinsey partner Ed Barriball said in a McKinsey on Government podcast, “Most companies and governments know who they buy from directly, but our research finds that more risk emerges from tier two, tier three, and tier four of the supply chain, which would be your supplier’s suppliers.”

The problem is that most organizations don’t have this level of details and granular data about indirect suppliers. Moreover, supplier information is considered proprietary. Hence the first step to assess risk and improve resilience is to map the end-to-end supply chain ecosystem. AI-powered geospatial analytics can help to identify tier 2 and tier 3 suppliers. And investing in tools for site monitoring that have automated anomaly detection will increase supply chain resiliency and improve operational efficiency.

3. Hyperconnected Supply Chain: Another trend is the advent of a hyperconnected supply chain and the necessary infrastructure, interconnected components at multiple layers for pervasive connectivity. Organizations are moving away from linear supply chains into connected supply networks where all linked partners share data across the ecosystem. The IoT, smart manufacturing and Industry 4.0 initiatives are acting as catalysts accelerating supply chain transformation, demanding real-time visibility and driving connectivity. The connected supply network leverages next-generation tools such as cloud-based digital supply chain platforms to sense demand signals and respond accordingly. Real-time transportation visibility appears to be a key priority for 3PLs, shippers, and customers, with the hyperconnected supply chain providing the fundamental underpinnings of visibility and resiliency.

We’ll look at the remaining trends in the next blog. In the meantime, be sure to check out how an international chemical company with complex operations across three continents significantly improved profits by using Orbital Insight's GO platform to monitor hundreds of competing chemical plants delivering timely, objective, and actionable insights about supply:

Digitally Tracking Chemicals Supply Chain Disruptions