- Orbital Insight Blog

- How do you adapt, restructure & modernize your supply chain?

Blog

How do you adapt, restructure & modernize your supply chain?

Rising costs, trade wars, environmental shocks, and unforeseen factory lockdowns will continue to hinder supply chains. Location intelligence can enable you to respond to change, improve visibility and transform into a connected supply network.

If you had asked supply chain leaders at Fortune 200 companies about the state of industry a few years back, the answer would have been driving cost efficiency, managing global networks of suppliers, and keeping tight control on inventory. Those were the days when lean manufacturing, just-in-time inventory management, six sigma, and globalization were at their prime. Then an earthquake and tsunami struck Japan leading to the Fukushima Daichi nuclear disaster in March 2011. Throughout Japan, manufacturing plants were closed, and the unfortunate event sent shock waves across the computer, electronics, and automobile industries worldwide.

Fast-forward to 2020, the CDC confirmed the first case of coronavirus on January 21st, and a few days later, WHO declared public healthcare emergency. Factory lockdowns, transportation network disruption, and panic buying became part of our life. Did you notice the similarity between these two unrelated events? Supply chain disruptions, a worldwide shortage of goods, and hampered just-in-time operations. These events expose global supply chains’ vulnerability and the urgent need to change the way most organizations run supply chains. Given the geopolitical tension, climate change, and trade restrictions, supply chain disruptions are likely to continue for the foreseeable future. How can supply chain leaders respond? What can they do to make their supply chains more robust, resilient, and responsive before the next disaster strikes?

One approach is holding more inventory, adding alternative manufacturing capacity, and expanding raw material providers. For example, many global auto suppliers responded to the 2011 Japanese earthquake by diversifying production and creating alternative production lines. With 30,000 components required to build a single car, that has been a massive undertaking.

Global enterprise strategy leaders, CIOs, and sourcing teams, in particular, are exploring ways to mitigate risk and have more granular visibility across their multi-tier supply chains. According to a Gartner report published before the covid pandemic, visibility and traceability across end-to-end supply chains were the most important funded supply chain initiative.

Today, visibility and traceability have become even more critical. As a supply chain leader, you need to understand anomalies, outages, and disruptions at your suppliers and your supplier’s suppliers, and your competitors. And this needs to happen in near real-time to allow efficient and cost-effective business decisions. Timely operational planning is crucial to maintain operations and to be better informed around pricing and supply.

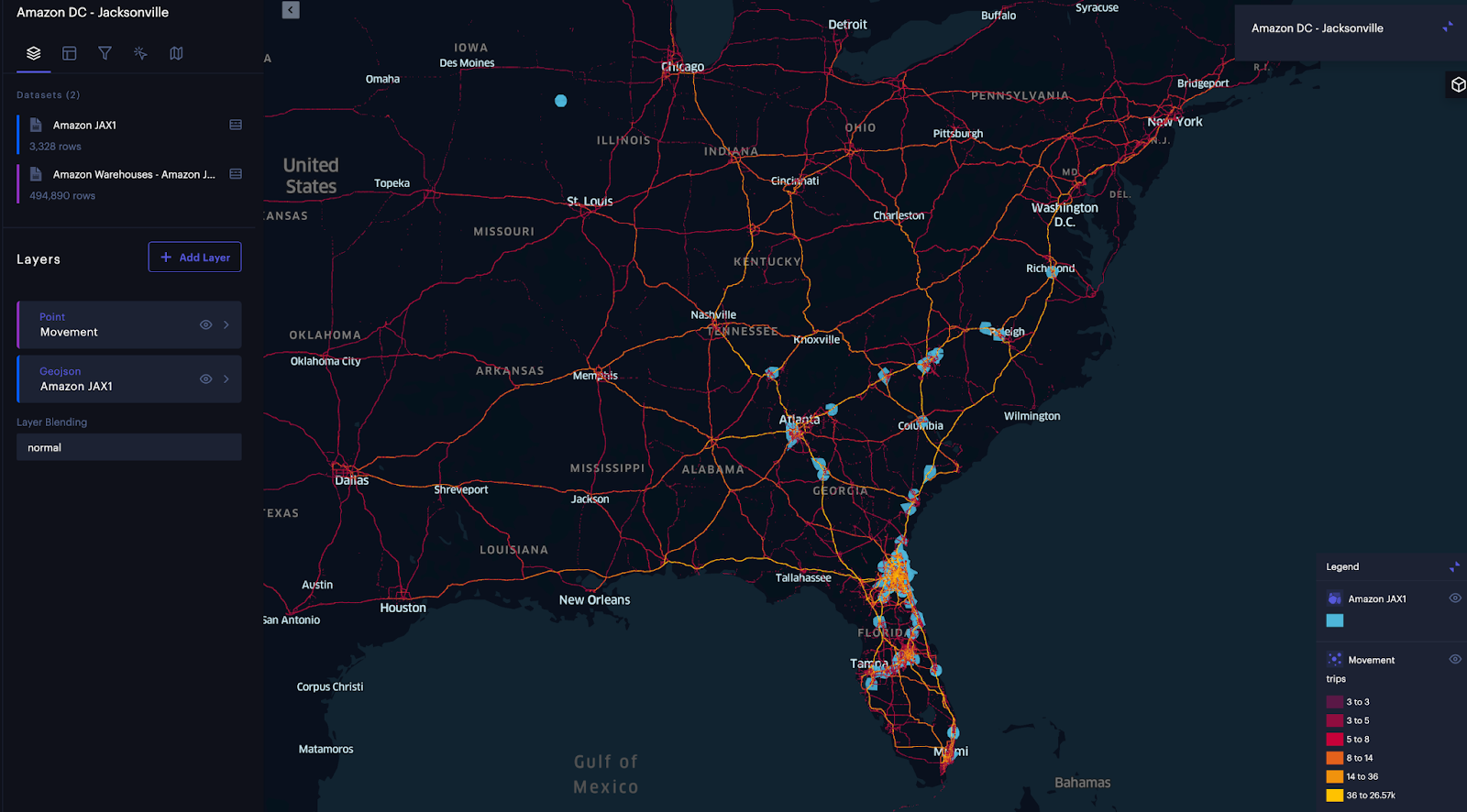

Did you know that location intelligence using geospatial analytics can help you to increase supply chain visibility, enhance traceability, and improve operational efficiency? By combining satellite imagery, computer vision, and multisource (IoT) data, an AI-powered geospatial platform can illuminate your supply chains, monitor daily activity levels, perform anomaly detection and reduce disruption risk.

An advanced geospatial analytics platform can enable you to monitor production activity, track shipments, understand and monitor supply chains and answer critical questions around risk:

- Map out end-to-end supply chain to see all suppliers, monitor risks/disruptions

- Make critical operational decisions in time based on pricing and supply data

- Identify key suppliers and visualize interdependencies to mitigate risk

- Which ports are having delays, where to reroute goods to improve utilization

- Identify ships that are taking longer to arrive, make alternate plans

Supply chain leaders can implement location intelligence tools to streamline operations. The next generation of supply chain intelligence solutions leverage AI, location data, and automation to take the complexity out of supply chain management. These solutions empower supply chain managers to analyze delivery patterns, spot warning signs from suppliers struggling to keep up with demand and check their financial health to identify alternatives quickly. The best supply chain intelligence solutions facilitate collaboration between sourcing, procurement teams, and GIS analysts to capture competitive insights and build long-term strategic differentiation.

However, only a few organizations are aggregating data from multiple sources, combining location analytics and machine learning techniques to analyze and monitor their end-to-end supply chains. For example, Unilever, one of the world’s largest consumer goods companies, uses satellite imagery, location data, and AI to track and monitor their raw material sourcing for Palm oil.

It’s time for consumer packaged goods, chemical, and automotive companies to leverage location intelligence for enhanced supply chain visibility and traceability. Novel location-based supply chain intelligence solutions can detect changes in the supplier ecosystem, uncover hidden patterns indiscernible to the naked eye, and deliver competitive insights at scale. And, supply chain intelligence will further expand the Industry 4.0 vision, accelerate smart manufacturing with digital, transparent, and connected supply chains. The best part is that the technology can also be applied to fight deforestation, promote responsible sourcing, and progress towards sustainability goals.

Curious to learn more about AI-powered geospatial analytics and how it can help you promote sustainability, improve supply chain visibility and resiliency, check us out:

Go deeper

- Download the eBook, 7 Keys to Your Supply Chain Success, and see how our customers, such as Unilever, Celanese, BP, and others, are using geospatial analytics to gain Supply Chain Intelligence

- Explore Supply Chain Intelligence

- Unilever's approach to tackling deforestation: In Southeast Asia’s Oil Palm Fields, Unilever teams with Orbital Insight to Fight Deforestation