- Orbital Insight Blog

- Cellphone Geolocation Offers Insight into Refinery Activity (or Lack Thereof)

Blog

Cellphone Geolocation Offers Insight into Refinery Activity (or Lack Thereof)

Even the slightest change in refinery activity can alter oil supply and demand models for those trading crude and refined products. Yet, for years, knowledge of unreported maintenance and unplanned refinery outages was hardly timely. Orbital Insight has changed that with the introduction of its geolocation surveillance through its platform, GO.

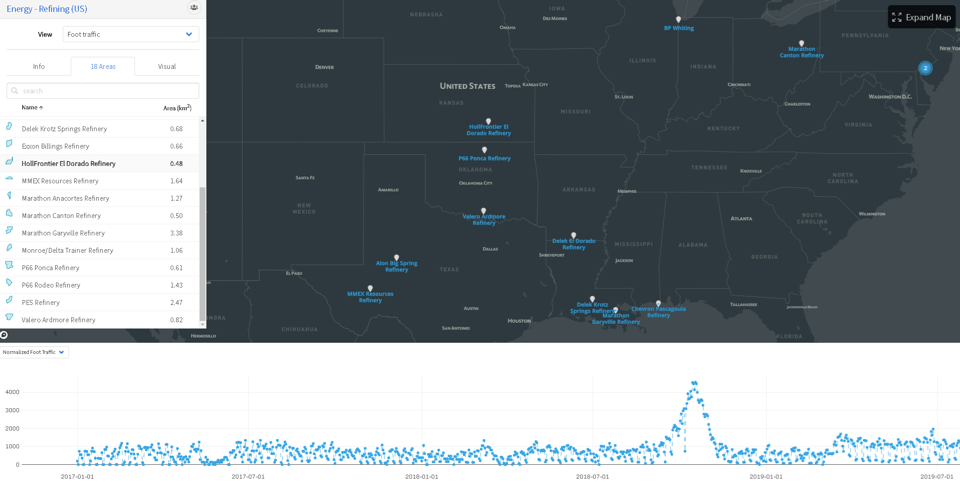

The foot-traffic data it mines from millions of device “pings” are reported in your specific area of interest, whether you’re interested in global refinery activity or just a specific area at an individual facility. The data are reported in an anonymized and aggregated format, showing the number of workers at each area of interest, and when that number spikes it could be an indicator of unplanned maintenance.

Tracking Refinery Disruptions

GO keeps a 24/7 watch on turnaround crews, overtime hours and extra weekend shifts at refineries to objectively identify relevant staffing changes. As a result, it is able to detect changes in scheduled maintenance activity up to three days before other reporting services, which either rely on anecdotal evidence or information from the refinery operators themselves.

Monitoring refinery disruptions or anomalies have become all the more important this year with processing plants staying offline longer than expected to meet new maritime fuel processing standards under the so-called IMO 2020, launching Jan 1. IMO 2020 aims to reduce air pollution from sea-faring traffic by lowering the current 3.5% sulfur content in marine fuels to 0.5%. The requirement to turn out low-polluting maritime fuels has constantly kept U.S. refinery runs under the 90%-and-above norm this in recent months, resulting in lower weekly outputs of key distillate fuels as well as gasoline.

All these have made GO’s continuous coverage of refinery activity all the more important to help industry participants build insights on operational transparency, product flows, and pricing.

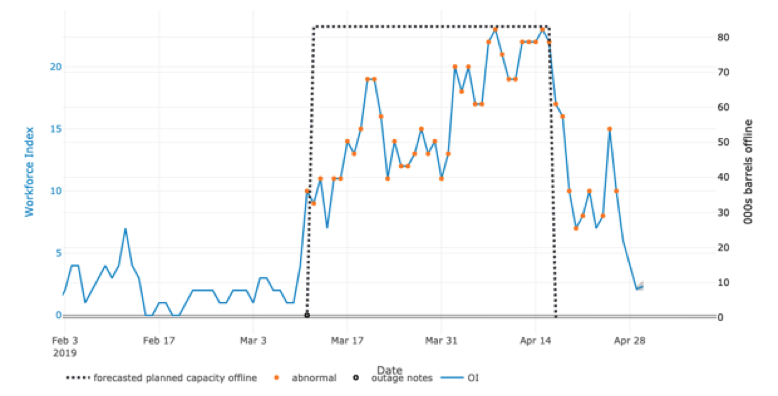

To give you an example of what we’re talking about, this spring, GO detected a two-week overrun on maintenance at Delek’s El Dorado refinery in Kansas, starting as planned on March 11 but finishing on April 27, instead of April 15 as scheduled.

Also in the spring, we had data showing HollyFrontier completing maintenance on its Tulsa East refinery in Oklahoma almost one month ahead of schedule, while Valero’s refinery in St. Charles, L.A. overran its completion target by more than two weeks.

GO’s refinery data can be localized to an Area of Interest to study specific anomalies. For instance, HollyFrontier’s Dorado Refinery (top left) was geofenced to track a surge of repair and maintenance crews. Customers can also see areas and units of a refinery that’s being worked on by identifying clusters of pings within the facility. HollyFrontier’s (bottom) completed maintenance at El Dorado was later confirmed as Unplanned Repairs/Malfunction through Bloomberg’s <REFO> function.

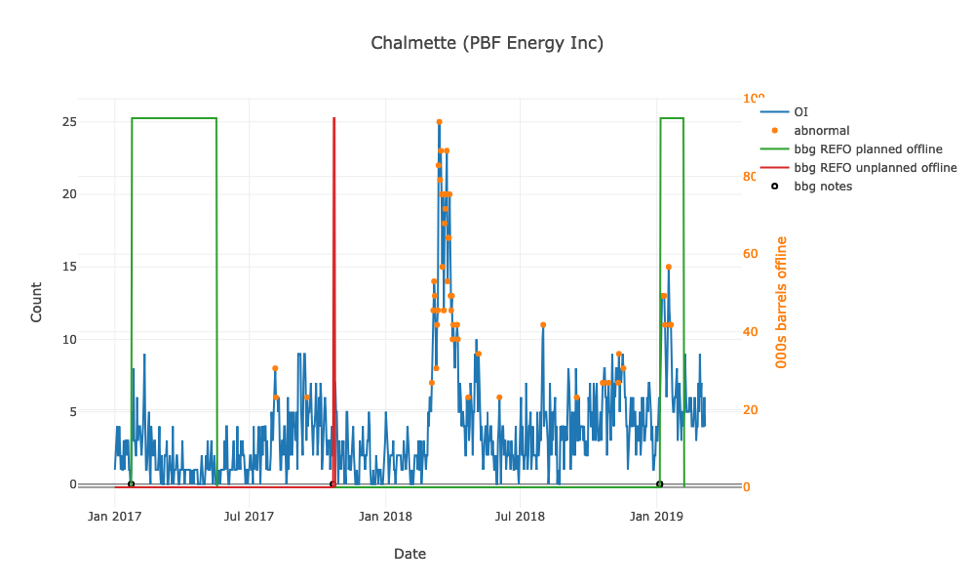

In another more widely reported incident, we detected early a sizeable spike in the number of mobile devices at the PBF Chalmette Refinery, located near New Orleans, from March to June 2018, corresponding to a turnaround that was absent in maintenance forecasts. News sources confirmed a week after the fact that a flaring event on March 10, 2018, “was the result of an accident at the facility during a “turnaround” maintenance project, and was not reported in advance to the state.” Having such information sooner will help energy traders better assess the impact on Gulf Coast refineries from similar incidents and enable them to make more timely and better-informed trading decisions.

GO’s traffic-data allows us to see the clear impact of outages from the surge of repair and maintenance crews onboard

A large refinery, for example, in addition to turnaround activities will also have thousands of day-to-day preventive maintenance activities, and several new construction or expansion projects underway — all running concurrently. A refinery’s profitability largely depends on being able to quickly schedule all the above and deploy resources across projects, locations, product lines, and divisions, to ensure projects are achievable to meet the business needs. If a turnaround in one plant impacts the production of a highly profitable product in another, profitability on the whole can suffer.

That’s why it’s critical to have supply production information as early as possible for market participants to decide on appropriate action or hedging. With a decisive time advantage, Orbital Insight GO is able to help provide that data at scale, monitoring the world’s refining activity.

While this blog post focused on monitoring refinery activity, this methodology is applicable to understanding facilities such as LNG plants, petrochemical plants, and mines. When paired with Orbital Insight’s suite of geospatial capabilities, GO users are able to track oil storage, the flow of inventories, refinery outages, and downstream demand to illuminate the first to last mile of the supply chain with objective, transparent, and timely data.

For more information on how to use Orbital Insight GO to illuminate the entire energy supply chain, please reach out to: support@orbitalinsight.com