- Orbital Insight Blog

- GO Tracks Construction Of World’s Largest MEG Petrochemical Plant

Blog

GO Tracks Construction Of World’s Largest MEG Petrochemical Plant

For those of you who missed our previous blog post, Orbital Insight GO Tracks America’s Fuel and Petrochemical Supply Chain, we outlined how anyone can run analytics on a self-selected area of interest ranging from the size of a country to an individual asset to gain an empirical understanding of that location.

AI and remote sensing are able to illuminate entire supply chains, from E&P activities, refining activity, transportation, all the way down to retail consumption. Research on a macro sector such as a basin may tip-off follow-on research to the micro. In this post, we will examine how an Orbital Insight GO user would gain significant value by gaining transparency into a critical chokepoint like a refinery.

Traditional data sources such as press releases can give the refining competitors and investors a glimpse into construction progress. However, the need for empirical, rather than anecdotal, information provides a time advantage needed to gain an edge in the market. Orbital Insight’s GO uses Artificial Intelligence to flag real-time changes to on-site activity that signals a disruption or acceleration in a workflow.

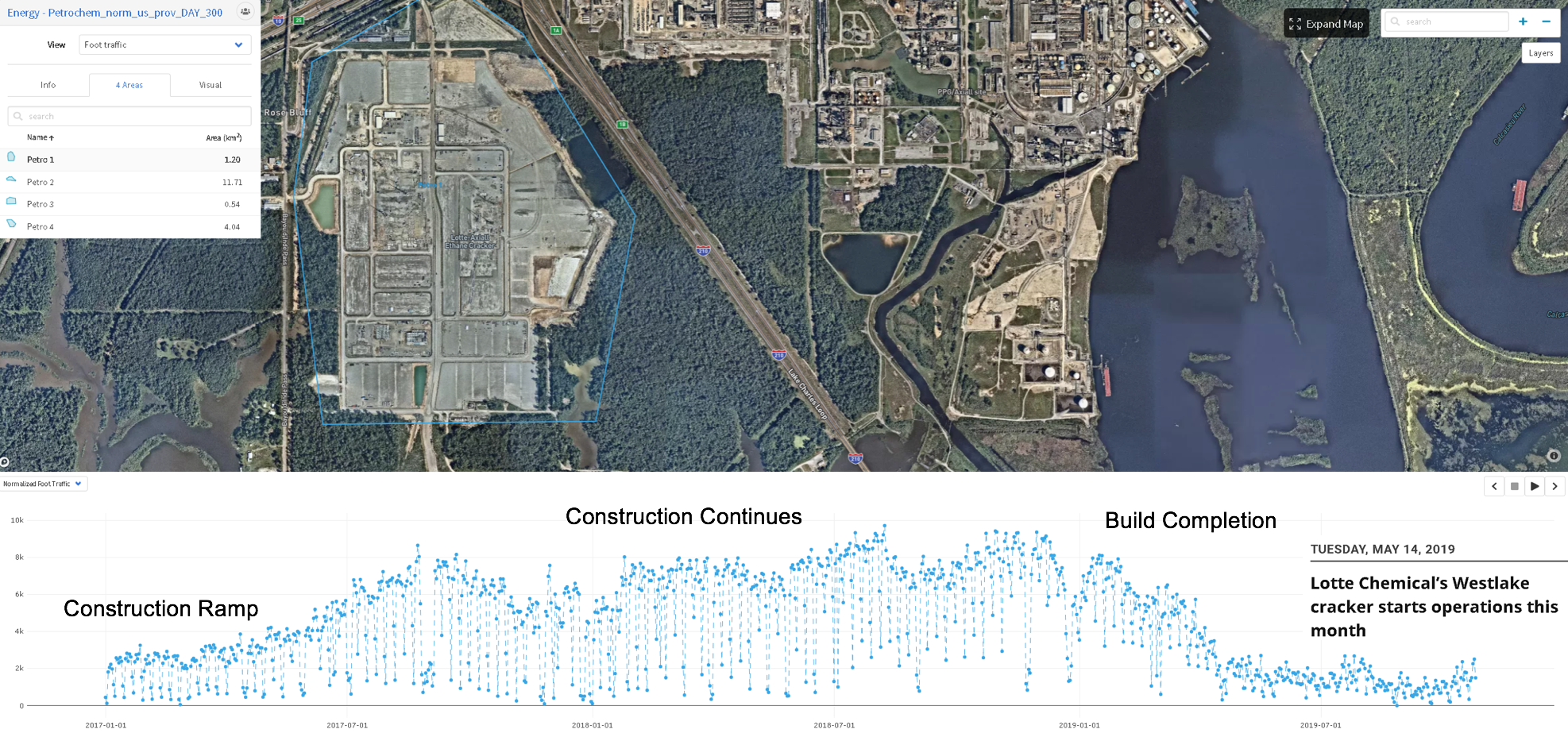

For example, using GO, you can monitor cellphone device “pings” at the Lotte Chemical and Westlake Chemical complex and instantaneously spot any unusual or lacking activity. The site is building the world’s largest refinery to manufacture the petrochemicals required for making bedding, furniture, carpeting, coatings and building materials and to track its construction progress takes minutes.

By creating a polygon for monitoring the ethane cracker, Orbital Insight GO can apply multiple algorithms to yield empirical data at the Lotte-Axial Ethane site. The lower pane shows activity readings for foot traffic captured within the area of interest. The data quantify clear workweek trends as well as ramp up and completion. Orbital Insight GO can enable ongoing monitoring of the world’s largest monoethylene glycol (MEG) plant, beginning operations in May, for unplanned outages and maintenance activity.

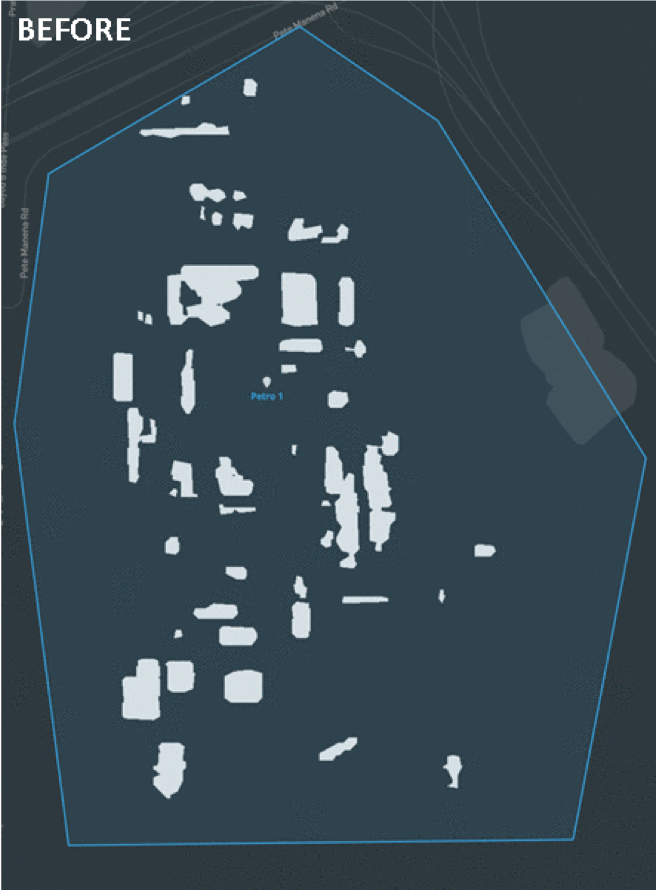

In addition to connected devices, Orbital Insight GO’s “one-stop-shop” of geospatial data also tracks the physical attributes of building construction through computer vision and satellite imagery. Our extensive partnership network enables both a higher frequency of monitoring and higher fidelity which shows the latest changes at the site.

The $3.1 billion project broke ground in June 2016, constructing a 250-acre complex with an ethane cracker and adding 250 direct jobs and 2,000 indirect jobs in Louisiana.

With so much at stake, the investors and other stakeholders in the project deserve timely updates on every aspect of its construction.

While this blogpost focused on a specific petrochemical refinery, this methodology is applicable to many types of self-selected facilities such as petroleum refineries, ports, manufacturing plants, and more.

For more information on how to use Orbital Insight GO to illuminate the entire energy supply chain, please reach out to support@orbitalinsight.com